I found this on Rossler Trans

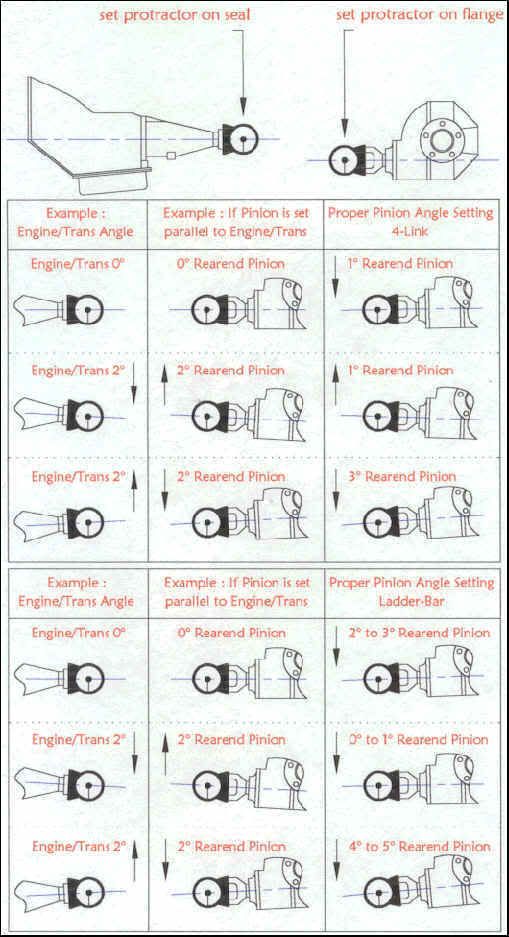

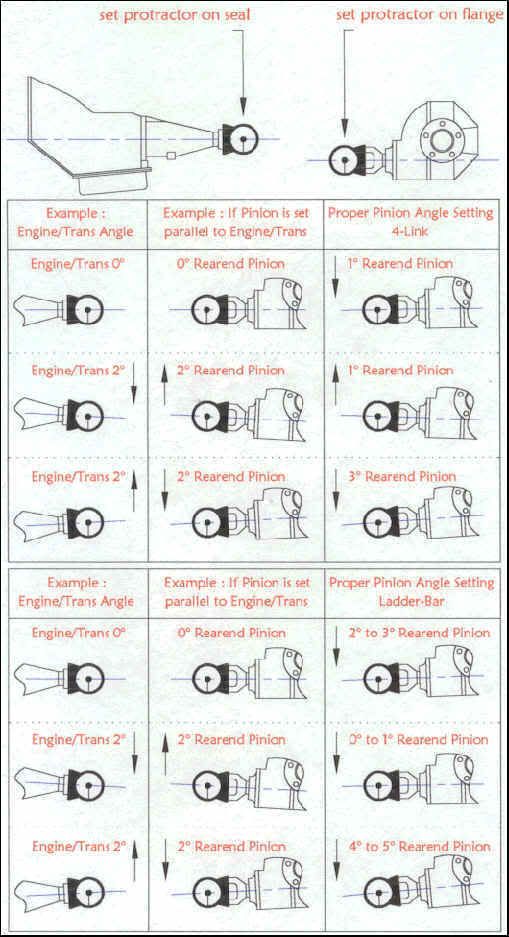

"Tired of breaking cases and drive shafts? There are many books that misled you on setting the pinion angle. For Drag Racing this is simple. You are trying to set the pinion angle to be parallel with the centerline of the engine & transmission on hard acceleration. To achieve this you must first figure out the parallel setting of the rear end to correspond to the angle of the engine & transmission, then add the proper amount of pinion angle. Add 1 deg. for 4-Link vehicles, 2 to 3 deg. for ladder-bar vehicles."

"Tired of breaking cases and drive shafts? There are many books that misled you on setting the pinion angle. For Drag Racing this is simple. You are trying to set the pinion angle to be parallel with the centerline of the engine & transmission on hard acceleration. To achieve this you must first figure out the parallel setting of the rear end to correspond to the angle of the engine & transmission, then add the proper amount of pinion angle. Add 1 deg. for 4-Link vehicles, 2 to 3 deg. for ladder-bar vehicles."

Comment