GM used this design for 6 model years which included some of the most historic cars of all time. Wonder what the engineers were thinking?

Ford and GM debated the design:

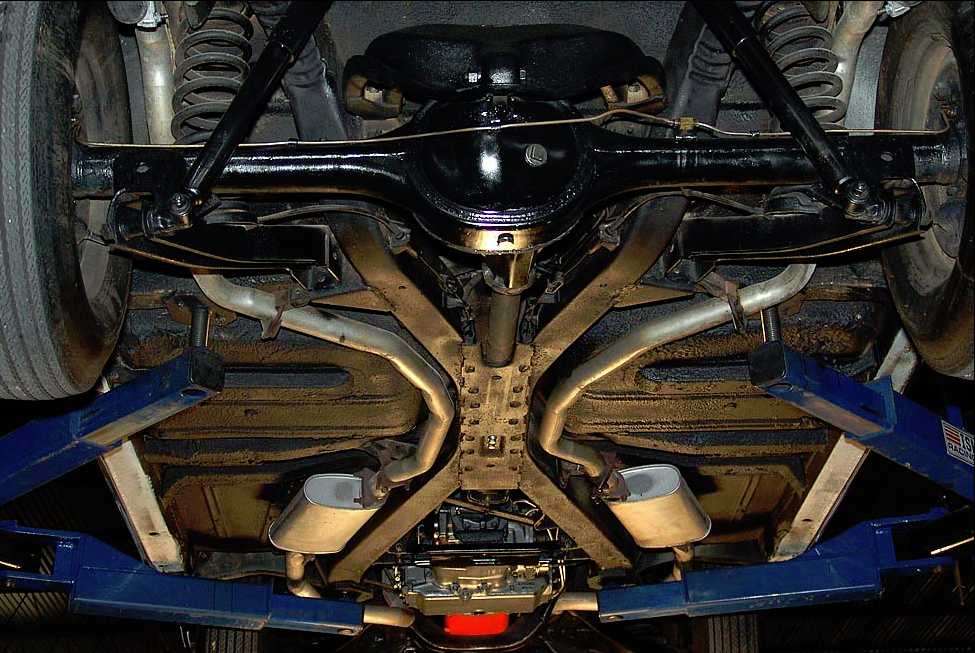

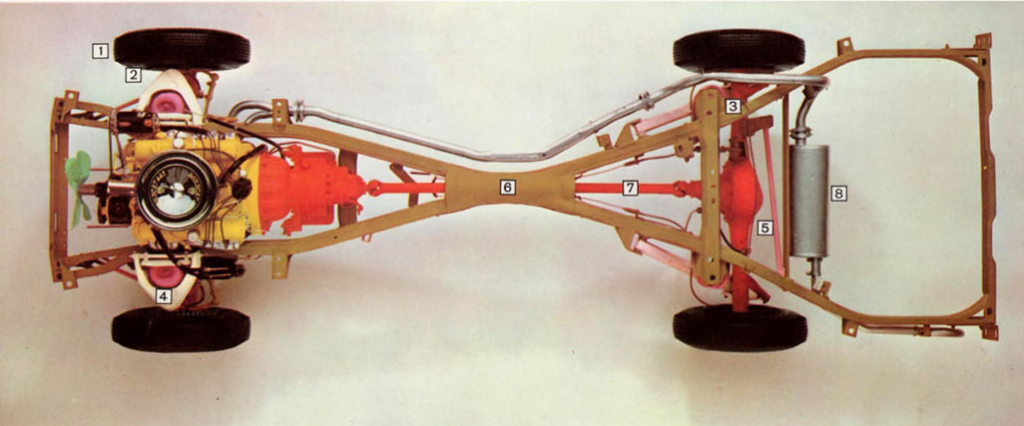

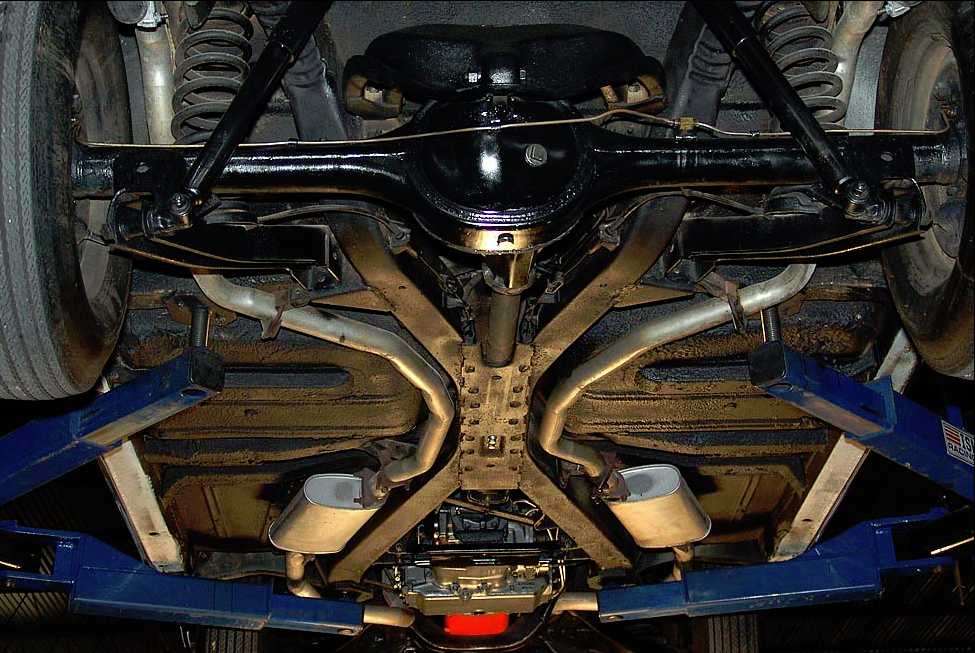

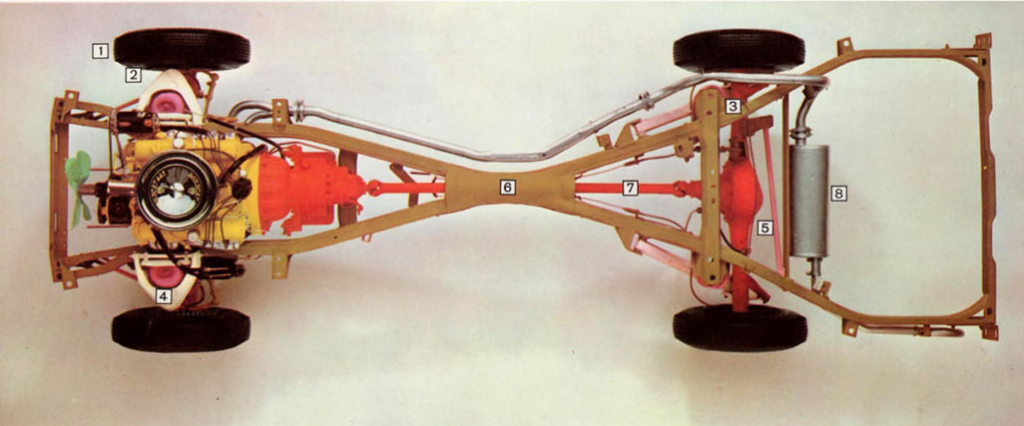

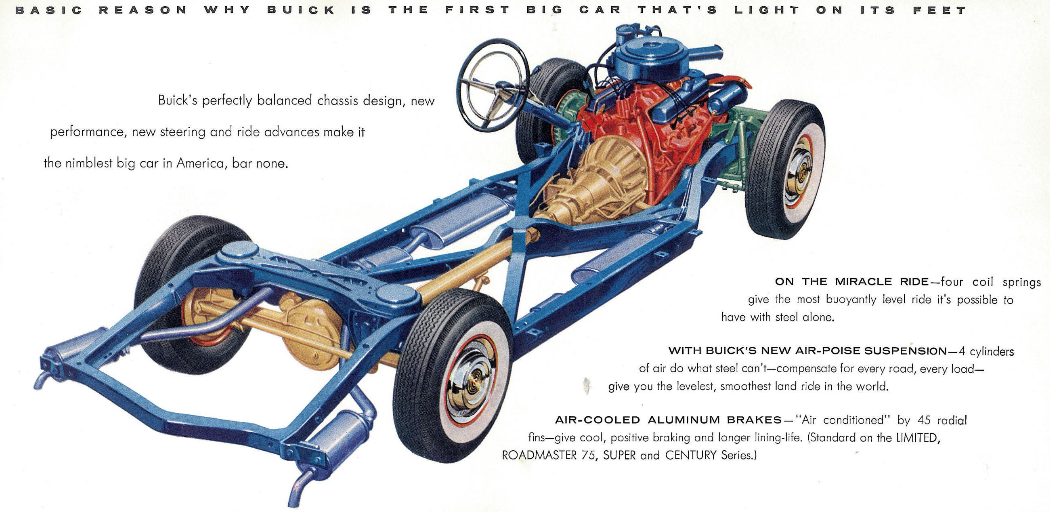

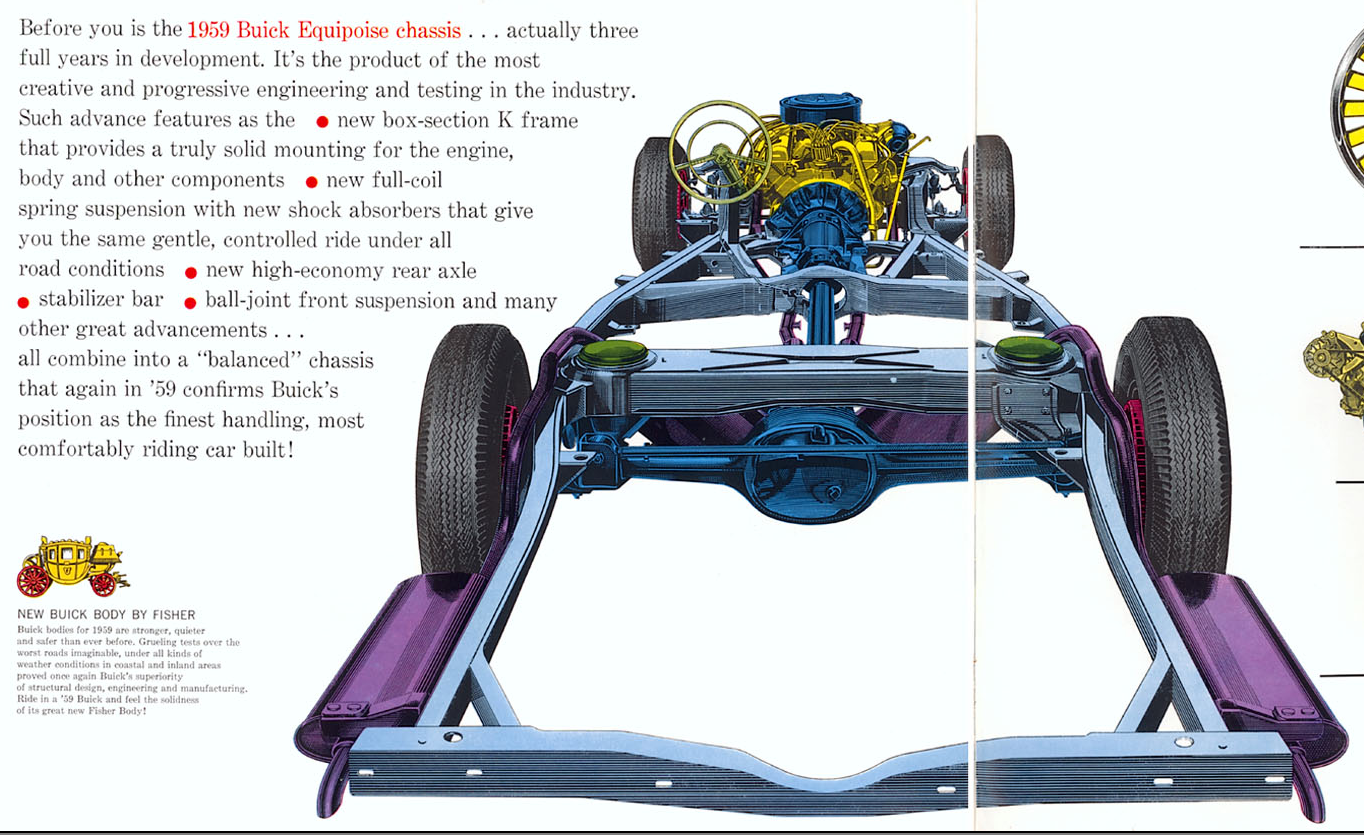

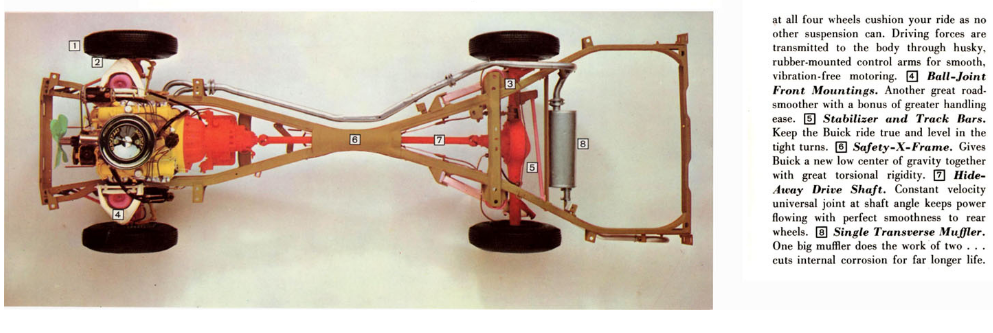

A case in point is the “X” or “cruciform” type chassis frame. This frame was introduced in 1957, primarily to reduce the problem of restricted headroom and difficult entry into the “low-profile” automobiles that were becoming popular after the mid-fifties. The X frame construction does not have side rails along the passenger compartment, as did most previous conventional frame designs. From the time the cruciform type frame was introduced, it was widely used by General Motors on Chevrolet, Buick, and Cadillac. The Ford Motor Company continued to use frames with side rails, and it was evident that the two companies held strongly different opinions about the two designs.

In the fall of 1959, a photograph of a Chevrolet Impala that was broken in half after striking a tree broadside was widely circulated in newspapers throughout the country. The frame had severed at the intersection of the X. The report of the General Motors investigators who rushed to the scene attributed the severance of the frame to the semi-airborne position of the car as it struck the tree. This had apparently allowed the engine mass to act as the head of a sledge hammer. At the General Motors engineering center in Michigan the conclusion was that “automobiles are not designed to withstand such tremendous lateral forces - this would be extremely uneconomical.”

General Motors spokesmen continued to defend the cruciform type frame as offering substantial resistance to side impacts because of the rocker panel and floor pan underbracing members — even though by 1965 all General Motors models except the Buick Riviera had abandoned the design in favor of the perimeter type. In 1960 the General Motors technical center offered proof that a unitized structure with side rails can also split into two pieces. A picture of a Ford Thunderbird, torn in half after slamming against a telephone pole and tree, was offered as evidence to critics of the X type frame.

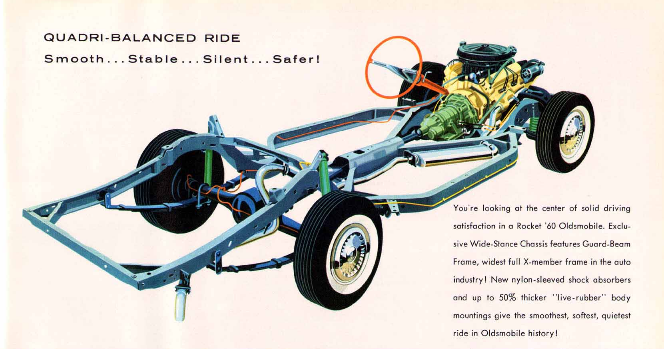

This comparison enraged Ford engineers. Fletcher N. Platt, a highly talented research engineer at Ford, retorted that the Thunderbird case involved a telephone guy-wire that had “acted as a knife on the entire body structure.” In contrast, he said, “the Chevrolet that broke in half failed at the center of the X frame after hitting a tree.” Platt said, “The X frame has no advantages from the standpoint of passenger protection. It requires less material to support the four comers of the car, but it is obviously less rigid and provides little lateral [side] protection to the passenger compartment.” He suggests consulting any “‘unbiased’ structural engineer regarding these two designs.” Mr. Platt might not consider Mr. Harry Barr, vice president for engineering of General Motors, qualified for the designation ‘unbiased,’ but Mr. Barr did admit grudgingly, under questioning, that the Oldsmobile perimeter type frame had some advantages over the Chevrolet X type frame in side-impact crashes at speeds of about fifteen miles per hour. Further proof that some General Motors engineers agreed with Ford’s Platt came in the form of an internal memorandum prepared by the Oldsmobile division in 1963 in which the Oldsmobile “guard-beam” frame was described as offering an “extra margin of protection” over the X type frames of Chevrolet, Buick, and Cadillac.

Ford and GM debated the design:

A case in point is the “X” or “cruciform” type chassis frame. This frame was introduced in 1957, primarily to reduce the problem of restricted headroom and difficult entry into the “low-profile” automobiles that were becoming popular after the mid-fifties. The X frame construction does not have side rails along the passenger compartment, as did most previous conventional frame designs. From the time the cruciform type frame was introduced, it was widely used by General Motors on Chevrolet, Buick, and Cadillac. The Ford Motor Company continued to use frames with side rails, and it was evident that the two companies held strongly different opinions about the two designs.

In the fall of 1959, a photograph of a Chevrolet Impala that was broken in half after striking a tree broadside was widely circulated in newspapers throughout the country. The frame had severed at the intersection of the X. The report of the General Motors investigators who rushed to the scene attributed the severance of the frame to the semi-airborne position of the car as it struck the tree. This had apparently allowed the engine mass to act as the head of a sledge hammer. At the General Motors engineering center in Michigan the conclusion was that “automobiles are not designed to withstand such tremendous lateral forces - this would be extremely uneconomical.”

General Motors spokesmen continued to defend the cruciform type frame as offering substantial resistance to side impacts because of the rocker panel and floor pan underbracing members — even though by 1965 all General Motors models except the Buick Riviera had abandoned the design in favor of the perimeter type. In 1960 the General Motors technical center offered proof that a unitized structure with side rails can also split into two pieces. A picture of a Ford Thunderbird, torn in half after slamming against a telephone pole and tree, was offered as evidence to critics of the X type frame.

This comparison enraged Ford engineers. Fletcher N. Platt, a highly talented research engineer at Ford, retorted that the Thunderbird case involved a telephone guy-wire that had “acted as a knife on the entire body structure.” In contrast, he said, “the Chevrolet that broke in half failed at the center of the X frame after hitting a tree.” Platt said, “The X frame has no advantages from the standpoint of passenger protection. It requires less material to support the four comers of the car, but it is obviously less rigid and provides little lateral [side] protection to the passenger compartment.” He suggests consulting any “‘unbiased’ structural engineer regarding these two designs.” Mr. Platt might not consider Mr. Harry Barr, vice president for engineering of General Motors, qualified for the designation ‘unbiased,’ but Mr. Barr did admit grudgingly, under questioning, that the Oldsmobile perimeter type frame had some advantages over the Chevrolet X type frame in side-impact crashes at speeds of about fifteen miles per hour. Further proof that some General Motors engineers agreed with Ford’s Platt came in the form of an internal memorandum prepared by the Oldsmobile division in 1963 in which the Oldsmobile “guard-beam” frame was described as offering an “extra margin of protection” over the X type frames of Chevrolet, Buick, and Cadillac.

Years later, I owned '60 Chevy Parkwood wagon w/235 I6. It had a three-on-the-tree w/factory overdrive. I used it to haul band equipment.

Years later, I owned '60 Chevy Parkwood wagon w/235 I6. It had a three-on-the-tree w/factory overdrive. I used it to haul band equipment.

Comment